Extruders

COMPREX mainly supplies two types of extruders:

– for plastic PVC, PE, PP, etc.

– for rubber

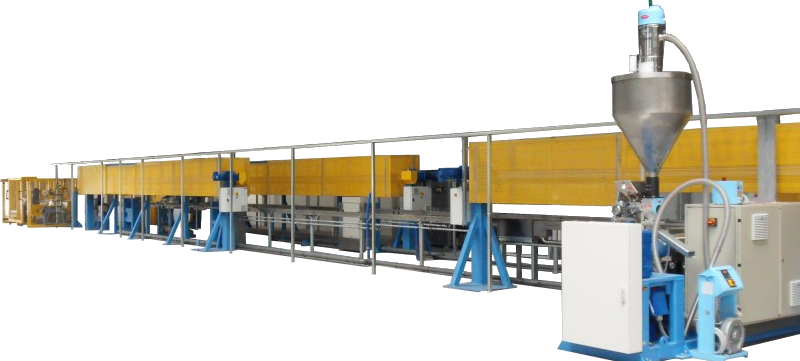

Extruders for plastic designed for cables are used to coat cores/conductors and cables, or for other products, to achieve the desired profile shapes. Extruders might be a part of processing lines or they can be supplied separately as a mechatronic package. In the first case, the machines are integrated with the control system of the line, otherwise there is a separately operating panel and PLC, the drive control being just for the extruder.

Extruders for plastic:

The smallest size of the extrusion screw diameter is .25mm and the production capacity is c.a. 10kg/h, the biggest size of the screw diameter can be up to 125mm and the capacity over 500kg/h.

Heating of the cylinders is resistance type and cooling is done through fans.

The standard sizes of the extruders are as follows: 25, 30, 35, 45, 50, 60, 70, 75, 90, 125

Extruders for rubber:

The standard sizes of extruders for rubber are as follows: 30, 60, 90, 120mm.

The construction is adjusted specifically for rubber – the screw is shorter and the temperature of the cylinder is regulated via an oil system in each temperature zone.

Additionally, in order to supply the rubber material through the entering hole, special calender rolls are used to insert the material inside the cylinder.

- Extruder for rubber fi30

- Extuder for hard extrudable plastics fi90

- Extruder fi120

- Extruder fi25

- Extruder for rubber fi90

- Extruder fi50

- Vertical extruder fi25

- Extruder fi70

- Extruder fi60

- Extruder fi70

- Extruder fi90

- Extruder fi30

- Extruder fi45

- Extruder for rubber fi120

- Extruder for rubber fi60

- Movable extruder fi80 x 30D for PE

- 5-layer extrusion cross-head for PERT-adhesive-EVOH-adhesive-PERT pipe production